The tradtional MSP family of ProMik® stands for highest quality and customer satisfication. Since the introduction of the In-System-Flash-Programmer in the early two thousands, the module has convinced through its high flexibility and great performance. The MSP family also adapts to market requirements and grows into a high-performance tool for boundary scan and functional test.

Long programming times can influence and slow down entire production processes. As soon as several production steps within the process require different runtimes, costs within manufacturing increase. This is one of the challenges that ProMik® has addressed. The in-system flash programmers are designed to comprehensively cover the electronics manufacturing toolchain by combining all test and programming requirements into one product. Whether in development for debugging, in prototyping for verification of samples or in series production for the production of ECUs - the MSP family convinces with its flexibility and functionality.

Integration of all flash and test functions in one in-system flash programmer

The MSP series is characterized by its versatile use in electronics manufacturing. The In-System flash Programmer can be used for flashing via test points as well as for flashing via automotive interfaces. The MSP is equipped with CAN-FD, Ethernet and LIN interfaces. In addition, the High-Speed Boundary Scan and the SMART ICT function can be used. The range of these features makes it ideal for parallel flash programming and testing.

ProMik®'s innovative device drivers can be extended with special functions that allow you to test components without direct test point access, as well as perform dedicated functional tests. In addition, ProMik®'s SMART ICT technology allows you to perform all boundary scan functions at the highest JTAG frequency (50MHz) with cable lengths of up to 1.5m between target and flash programmer.

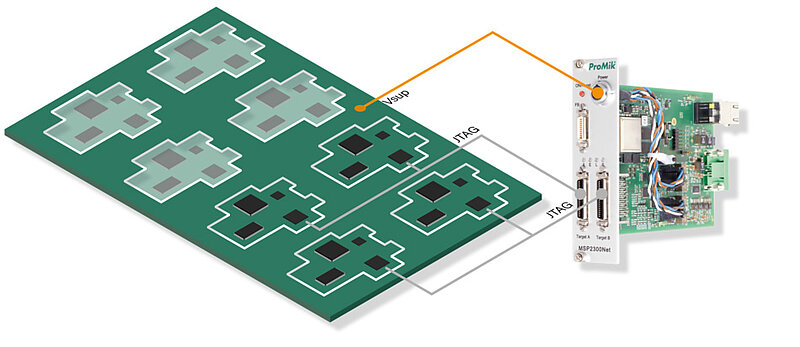

Flash-Programming_MSP2300Net_Panel

The integrated power supply of the MSP2300Net is particularly efficient for high benefit programming. Due to the availability of four independently adjustable channels, the parallel programming and module test of four control units can be ensured even with maximum I/O occupancy.

Balluff GmbH / BCS Automotive Interface Solutions / Bosch / Brose Fahrzeugteile GmbH & Co. KG / Continental /

Freetech Intelligent Systems / Helbako / Hyundai MOBIS / Jabil Circuit, Inc. / Kimball Electronics / Kostal Automobil

Elektrik / Küster Automotive / Kyungshin Corporation / Lear / LG Innotek / Magneti Marelli / Mando Hella /

Marquardt / Mekra Lang / Melecs EWS / PIA Automation / Preh / Preh Joyson Automotive / S&T Motiv Electronics /

SL Corporation / TRW Automotive / Valeo / Veoneer / Visteon / Yura Corporation / ZF Group / Zollner Elektronik AG